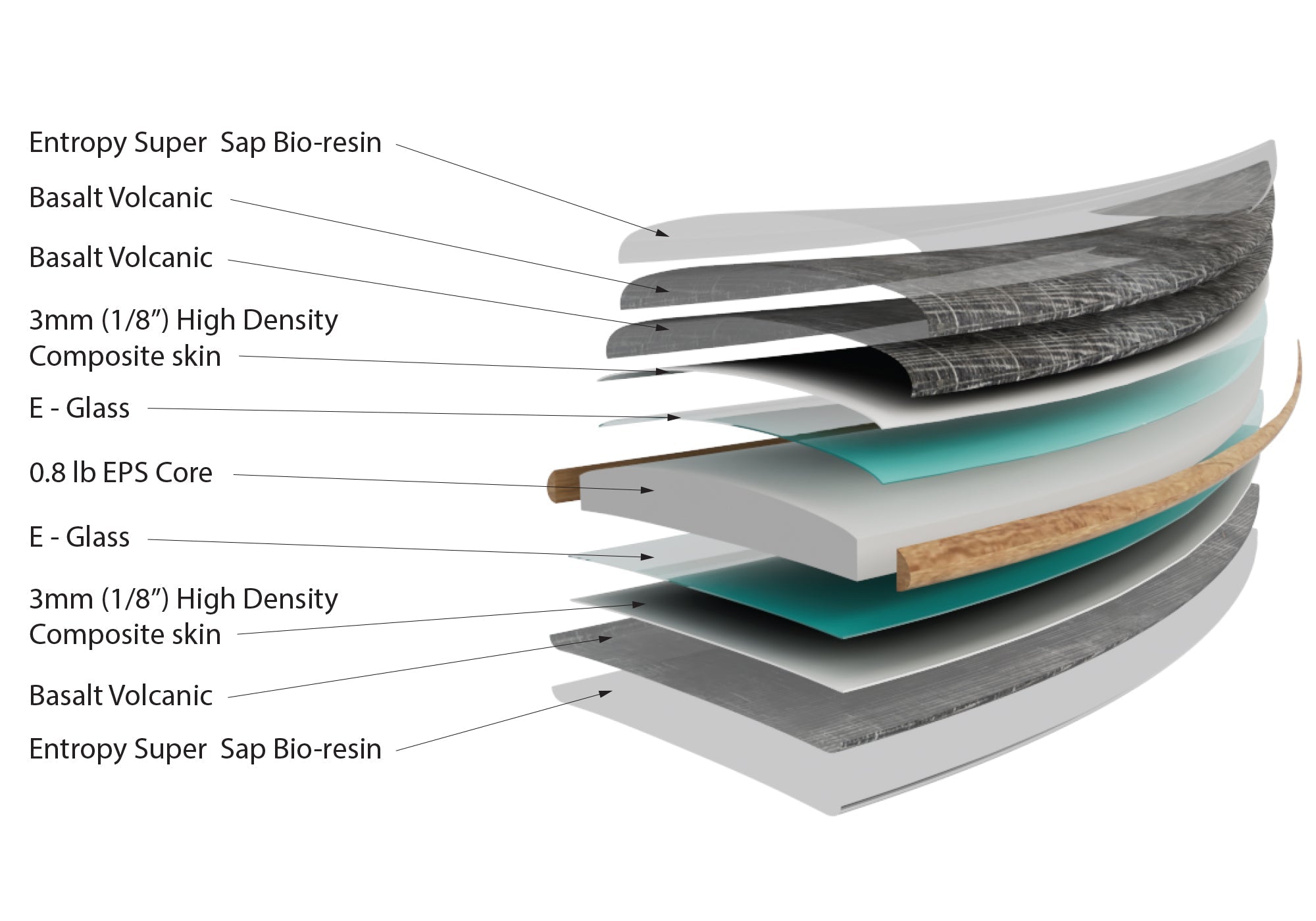

Volcanic Technology

Performance

Volcanic Technology

Construction

Volcanic Technology

Core Compatibilty

Shop the Collection

VOLCANIC TECHNOLOGY

Sci-Fi 2.0

Sale price€880,00 EUR

Regular price

Mashup

Sale price€880,00 EUR

Regular price

Seaside

Sale price€880,00 EUR

Regular price

Sweet Potato

Sale price€880,00 EUR

Regular price

Too Fish

Sale price€880,00 EUR

Regular price